Listen Now

Issue

The production of metals and minerals enables modern life and its technologies. Computer chip production, for example, uses as many as 60 different minerals [1]. Tailings, the material remaining after the extraction of the desired metals or minerals production is part of mining and minerals processing. Tailings require engineered solutions for their safe management [2]. This paper reviews three of the most common types of tailings facilities.a

Background

Modern tailings facilities are engineering projects which comply with specific design, safety, and environmental control regulatory requirements. Responsible tailings management considers specific characteristics of tailings, water management, and the processing method. Engineers design each tailings facility based on site-specific environmental, climatic, seismic, and geologic conditions, ore type, processing method, production rate, geochemistry, and topography. Mining companies employ engineering expertise, technological monitoring, and oversight to ensure that these structures are designed, constructed, operated, and monitored, and are performing in a manner that minimize risks to employees, communities, and the environment.

Tailings facilities during mine operation and afterward are the responsibility of mining companies. Government agencies regulate tailings and set minimum design standards. Tailings facilities are often a key element in the regulatory process governments employ to ensure the environmental effects are identified and considered before regulatory approval. The design, construction, and operational performance of a tailings facility is subject to continuous examination and periodic reviews [3].

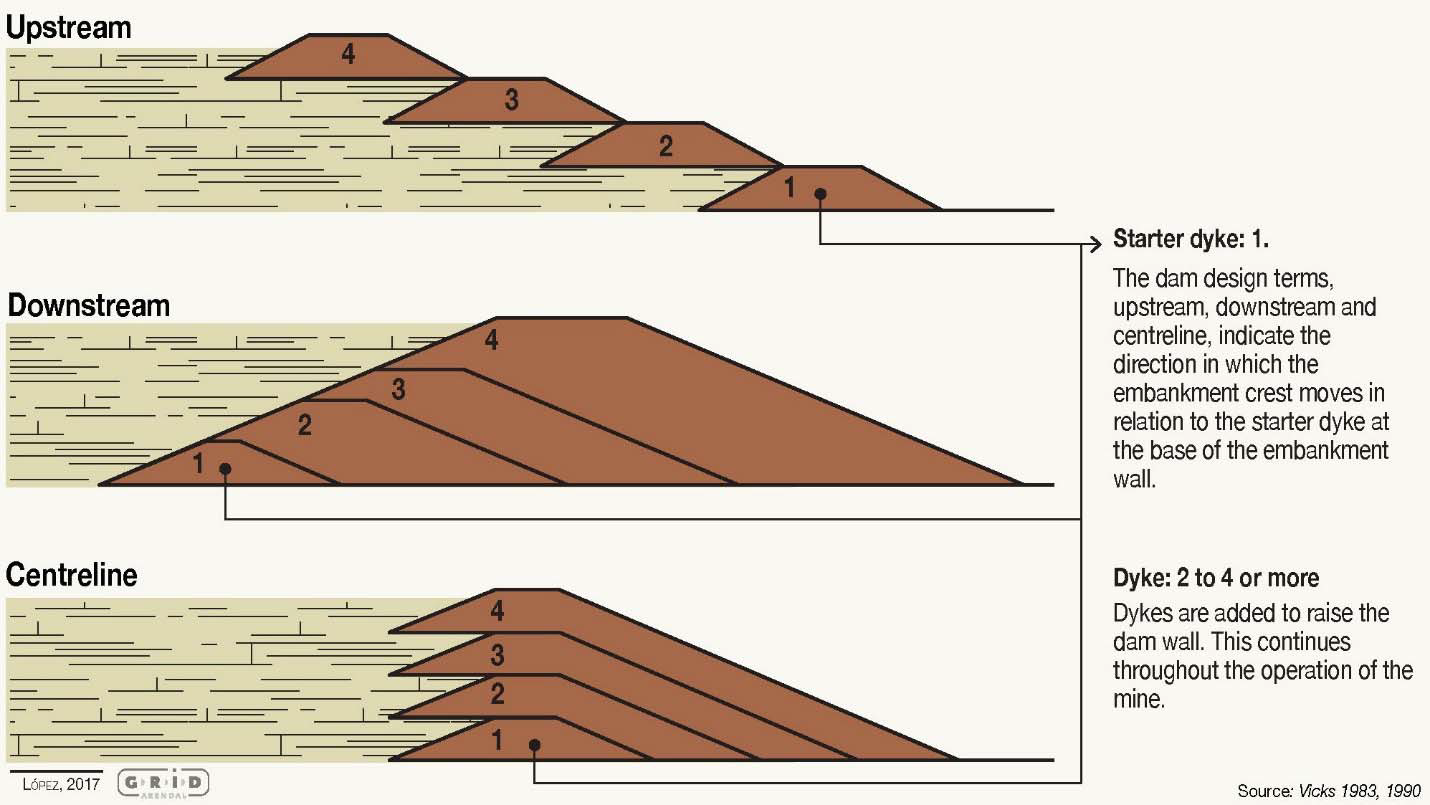

Tailings generally requires the construction of a dam or embankment, using one of three construction methods shown in Figure 1, or some combination thereof. The construction method is named based on the direction the dam’s crest moves as additional levels (dikes) are added.

(1) Upstream Construction: The dam crest progresses upstream as the height of the tailings facility increases. Tailings adjacent to the dam must be well- drained and may therefore be used to support subsequent levels as the dam is raised.

(2) Downstream Construction: The dam crest progresses downstream as the height of the tailings facility increases. The dam is constructed and supported on top of the previously placed material.

(3) Centerline Construction: The dam crest is raised vertically. The dam’s crest is maintained as the height increases. The upstream portion is constructed on top of previously placed tailings while the downstream portion of the dam is constructed on previously placed materials.

Figure 1. Types of Sequentially Raised Tailings Embankments from S.G. Vick 1990 as cited in Roche, C., Thygesen, K., & Baker, E. 2017 [4]

SME Statement of Technical Position

-

SME recognizes tailings management and storage as an essential part of the mining process.

-

Tailing facilities must be designed, constructed, operated, and closed using substantial engineering expertise, subject to appropriate corporate and regulatory oversight to minimize the risk to the mining workforce, neighboring communities, and the environment.

-

The safeguards applied to tailings facilities must be subject to continuous improvement, including lessons learned from past tailings structure failures, to prevent their recurrence.