Why the U.S. Needs a National Materials and Minerals Council

Based on the Recommendations of the

May 30, 2024 Roundtable Discussion of Mining Technical and Policy Experts

September 2024

Table of Contents

Executive Summary

1. Introduction

2. Background and Historical Overview of the USBM

3. Why the U.S. Needs an Entity Coordinating Federal Minerals Research

4. Federal Minerals and Mining Research – Then and Now

5. The IWG Report Underscores the Need for a Federal Minerals Group

6. The Roundtable’s Recommendations for NMMC Minerals Research

7. The U.S. Needs a Federal Minerals Entity to Compete on the World’s Stage

8. Critical Materials and Critical Minerals Legislative History Overview

9. Creating a National Minerals and Materials Council within the Executive Office of the President’s National Economic Council

10. The Bipartisan Infrastructure Law Already Authorizes Many of the Functions of the Former U.S. Bureau of Mines

11. Summary of the Roundtable’s Findings

Executive Summary

As summarized below, a group of mining technical and policy experts (Experts) participated in a May 30, 2024 roundtable discussion (Roundtable) hosted by the Society for Mining, Metallurgy & Exploration (SME) at its headquarters in Englewood, CO. The discussion focused on why the federal government needs a new Executive Branch entity to provide advice and coordination on minerals and mining issues, suggested the best place for this entity within the Executive Branch, highlighted the compelling public interests in creating this new entity, and identified the following reasons for a new entity within the Executive Branch:

- The U.S. has no centralized federal department or agency with the requisite mining and mineral processing expertise to assist the Executive Branch and Congress in developing coordinated mining policies responsive to the country’s mineral needs.

- A new centralized minerals entity is urgently needed to coordinate existing federal mineral programs, which are scattered throughout several executive branch departments and agencies, to identify and fill the gaps in the country’s current mineral and mineral processing research and development (R&D) programs, and to increase domestic mining and mineral processing in order to reduce our dependency on imported minerals.

- Establishing a Director of Minerals (Director) to lead a new entity called the “National Materials and Minerals Council” (NMMC) within the Executive Office of the President’s (EOP’s) National Economic Council (NEC) would achieve a whole-of-government approach to providing policy and technical input on issues pertaining to the broad array of materials and minerals that are indispensable to our economy and national security.

- NMMC and its Director would function as an executive-level, unbiased, and fact-based advisor to help Congress and Executive Branch officials develop internally consistent U.S. mineral policies and programs in coordination with all cabinet-level executive offices and their respective departments and agencies.

- NMMC would also be tasked with coordinating a federal minerals research program focused on strengthening U.S. mineral supply chains in order to reduce our dangerous reliance on foreign minerals and to meet the skyrocketing mineral demands projected for the next several decades to support the objectives to transition to a clean energy economy.

- NMMC’s research functions would help manage and coordinate third-party research programs currently underway operating with federal grants and loans and, as funding allows, new in-house research on broad materials and minerals issues with widespread applications that the private sector is unlikely to undertake.

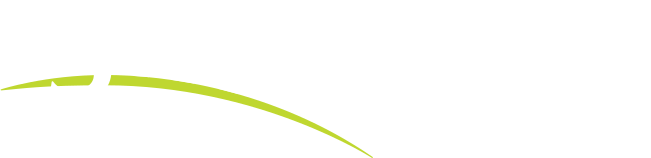

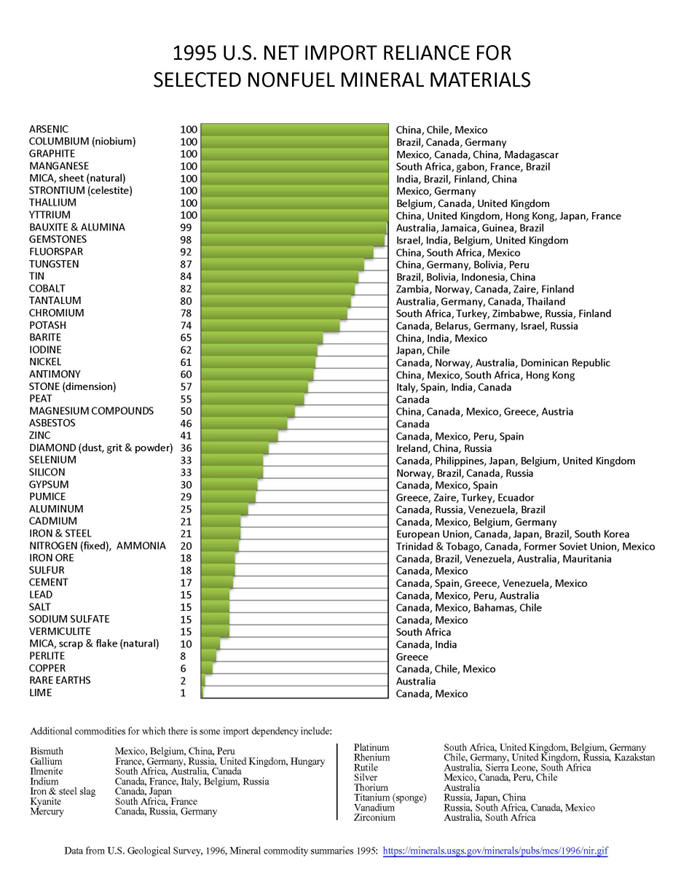

- Since Congress stopped funding the U.S. Bureau of Mines (USBM) in 1996, U.S. reliance on foreign minerals has increased dramatically, which can be readily seen by comparing the U.S. Geological Survey’s (USGS) 1995 and 2023 mineral import reliance charts.

- Today, the U.S. imports many minerals from adversarial nations, including China and Russia, and is between 50 and 100 percent reliant on foreign sources for 49 critical minerals. In 1995, the U.S. was similarly dependent on foreign countries for just 24 minerals.

-

- The demise of the USBM is one of the reasons for the country’s unsustainable dependency on foreign countries for the minerals needed to address the skyrocketing demand for minerals to support national defense and energy transition goals.

- Between 1910, when Congress created the USBM, and 1996, the USBM was the primary federal agency conducting and coordinating scientific research and disseminating information on the extraction, processing, use, conservation, and recycling of mineral resources. The USBM effectively conducted innovative and transformative R&D in a manner beyond the capability of any single private company to improve extraction techniques, environmental sustainability, and worker safety.

- The U.S. currently lacks adequate federal mining and mineral expertise and research capabilities because many of the former USBM’s technical and research functions were not assigned to other federal agencies.

- Although some USBM functions and equipment were transferred to the Department of Energy (DOE), Congress has not appropriated sufficient funding over the past three decades to support the country’s mineral needs.

- The September 2023 Interagency Working Group Report, Recommendations to Improve Mining on Public Lands, says a USBM is “needed to revitalize domestic mining,” noting that in the late 20th century, the U.S. lost its position as the global leader in mining production and as the main developer of cutting-edge mining technology.

- The absence of a federal minerals entity makes the U.S. less competitive on the world’s stage because most nations have a Minister of Mines or a centralized mining authority charged with developing mineral policies to ensure these countries have robust mining industries.

- Mining education has declined significantly since the demise of the USBM, with only 14 U.S. universities currently offering undergraduate programs in mining and metallurgy compared to 20 in 1995 and 25 in 1982.

- Congress has recently appropriated trillions of dollars in the 2021 Bipartisan Infrastructure Law (BIL), the 2022 Inflation Reduction Act and in the 2022 Chips and Science Act to support critical minerals programs and R&D, but these efforts are not well coordinated and lack strong central leadership.

- The DOE, the Department of Defense (DOD), the National Science Foundation, the Department of the Interior (DOI), and other agencies have ongoing mineral R&D programs that are largely uncoordinated.

-

- Some of the R&D funding is outsourced to academia and the private-sector without having the necessary federal expertise to oversee how this money is being spent, to coordinate these research efforts to achieve maximum synergies, to provide technical input and guidance to enhance research outcomes, or to disseminate information about successful research and transfer technology.

-

- Very few critical minerals R&D resources are earmarked for upstream critical minerals activities (e.g., exploration and mining).

- The Energy Act of 2020 defines and distinguishes between critical materials and critical minerals, making the DOE responsible for critical materials and development of a critical materials list and the DOI responsible for critical minerals and development of a critical minerals list.

- The Director’s responsibilities and the NMMC’s charter must include both critical materials and critical minerals as well as materials and minerals not currently included on either list due to the dynamic nature of criticality.

- Given the breadth of materials and minerals activities across the federal government, the Director and NMMC need to operate out of the EOP rather than being headquartered in either the DOE or the DOI given these departments have specific jurisdictions that distinguish between critical materials and critical minerals.

- Putting the Director and the NMMC in the EOP’s NEC would be the best way to achieve inter-departmental synergies and facilitate the participation of other cabinet-level executive offices like the Departments of Defense, Commerce, and State, and agencies involved with materials and minerals issues.

- This placement makes sense as mining is at the front end of every supply chain overseen by the NEC including infrastructure, manufacturing, housing, and technology and innovation.

- Section 40210 of the Bipartisan Infrastructure Law of 2021 establishes the Interagency Subcommittee on Critical Minerals and describes many research functions that are similar to the mining and mineral processing research mission of the former USBM.

- Congress could amend Section 40210 to:

- Rename the Interagency Subcommittee on Critical Minerals the NMMC;

- Authorize the Director and NMMC to take a whole-of-government perspective on materials and minerals policy issues;

- Add the NMMC and its Director as a new core element of the NEC;

- Designate the Director and NMMC as the federal materials and mineral policy clearinghouse; and

- Appropriate funds to operate the NMMC to:

- Provide mineral policy advice to the President, Executive Branch Departments, and Congress; particularly on policies necessary to secure materials and minerals supply chains, ensure consistency across multiple departments and agencies, and eliminate barriers to mineral development;

- Coordinate existing DOE, DOD, DOI and other materials and minerals R&D programs;

- Conduct NMMC-led materials and minerals research programs comprised of both in-house R&D and supervision and coordination of outsourced materials and minerals R&D programs and loans;

- Develop Mineral Land Assessments to evaluate the potential for economic mineral development on lands being proposed for mineral withdrawal;

- Perform resource evaluations on other public lands to assess their potential for economic mineral development; and

- Assist federal regulatory agencies evaluate technical issues associated with permit applications for mining and mineral processing operations.

1. Introduction

This concept paper discusses the need for a Director of Minerals (Director) and the National Materials and Minerals Council (NMMC) to be located within the Executive Office of the President (EOP) and staffed with policy and mining technical experts recruited from the private sector, federal agencies and departments, and academia. The Director and NMMC would be charged with taking a whole-of-government approach to performing the following materials and minerals functions:

- Provide policy advice and technical input on domestic materials and minerals to Congress, the President, and to Executive Branch agencies and departments and to assist Congress in fulfilling its oversight duties to ensure that taxpayer monies on minerals projects are being wisely spent;

- Serve as the clearinghouse that coordinates the efforts of the numerous federal agencies and departments that are involved with mineral issues to achieve more consistency, synergy, and efficiency; minimize inconsistencies, overlap, duplication; and remove barriers to mineral development;

- Perform in-house materials and minerals R&D to increase domestic mining and mineral processing to improve mineral recoveries, to enhance environmental protection and reduce environmental impacts, to ensure worker health and safety, and to optimize mine reclamation outcomes;

- Coordinate technical assistance and oversight on third-party critical materials and critical minerals R&D subsidized with federal grants and loans to capitalize on these investments of taxpayer dollars and to ensure timely technology transfer;

- Coordinate the evaluation of the economic mineral development potential of federal lands being considered for withdrawal from mining or subject to proposed federal land management designations that would limit mineral exploration and development;

- Help identify federal lands with high development potential for critical materials and minerals and make this information available to the public to stimulate private-sector exploration of these lands and to inform federal land management agencies’ (e.g., the U.S. Bureau of Land Management’s and the U.S. Forest Service’s) land use and resource management plans; and

- Assist federal regulatory agencies (e.g., the U.S. Bureau of Land Management, the U.S. Forest Service, the U.S. Environmental Protection Agency, and the U.S. Army Corps of Engineers), evaluate technical issues associated with permit applications for mining and mineral processing operations and to help facilitate the permitting process.

On May 30, 2024, the Society for Mining, Metallurgy & Exploration (SME) convened a Roundtable with mining technical and policy experts (Experts) including representatives from industry, academia, government and non-government organizations including former U.S. Bureau of Mines (USBM) employees to discuss the possibility of reestablishing a government agency or office that would be responsible for many of the duties once performed by the USBM. The Experts included mining engineers, metallurgists, environmental engineers, geologists, mineral economists, mine permitting and regulatory specialists, health and safety professionals, lawyers, and government affairs and policy specialists. This meeting highlighted many of the Nation’s losses in the mining and mineral development sector due to the closure of the USBM and also noted many of the gains the country could achieve with a new minerals agency or office.

The Roundtable was influenced by the work of the Interagency Working Group (IWG) comprised of the Departments of the Interior, Agriculture, Commerce, Energy, and State, and the U.S. Environmental Protection Agency, the U.S. Fish and Wildlife Service, the Army Corps of Engineers, the Council on Environmental Quality, and the National Economic Council. The IWG published a report in September 2023, entitled Recommendations to Improve Mining on Public Lands.1 This report cites the need for a USBM as “an issue needed to revitalize domestic mining:”

“At the end of the 20th century, the U.S. lost its position as the global leader in mining, both in terms of total production and the development of cutting-edge mining technology .... The infrastructure necessary to restart the domestic mining industry has atrophied with the increased offshoring of mining .... (IWG Report, pages 90-91)

It is the objective of this concept paper to explain the need for a new federal materials, mining and minerals entity that would centralize the focus of the U.S. government’s expertise and knowledge in materials, mining, and minerals and advocate for establishing such an entity in order to: increase domestic mining and mineral processing; strengthen domestic mineral supply chains; reduce the country’s reliance on foreign minerals; and lead to more consistent and effective U.S. minerals policies.

For the remainder of this concept paper, the terms “materials” and “minerals” are used interchangeably without distinction and without regard to whether specific materials and minerals are included in DOE’s current Critical Materials List or in DOI’s current Critical Minerals List.

2. Background and Historical Overview of the USBM

The USBM was established in 1910 in response to several mining disasters. For the following 85 years, the USBM conducted essential research related to mining and mineral processing, metallurgy, environmental remediation, and mine worker safety and health. In 1995, the U.S. Congress voted to cease funding the USBM. Although some of its essential functions were transferred to other agencies, other functions were permanently terminated or have not been funded by Congress for decades. Consequently the federal government no longer benefits from the comprehensive approach to domestic minerals, mining, and mineral processing that the USBM used to provide. The resulting substantial decline in domestic mining and mineral processing makes the U.S. vulnerable to materials and minerals shortfalls, putting our national security and economy at risk.

In the nearly three decades since the closure of the USBM, the U.S.’ dependence on foreign nations for minerals essential to the stability and security of the Nation’s economic and national security has increased dramatically as shown in Figure 1 (all figures are at the end of this document), which compares the 1995 and 2023 USGS, mineral dependency charts. The U.S. currently lacks the ability to mine and process many of the 50 minerals deemed “critical” by the USGS and is 100 percent reliant on foreign sources for 15 of these minerals. In 1995, when the country still had a USBM, the U.S. was 100 percent reliant on foreign nations for just eight minerals. The substantial increase in the Nation’s reliance on imported minerals is due in part to the demise of the USBM which provided federal support to conduct research that was essential to the health and viability of the domestic mining industry.2

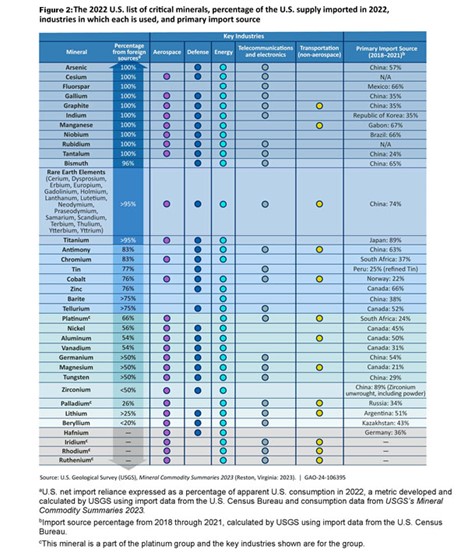

Figure 2 from the July 2024 U.S. Government Accountability (GAO) Report entitled “Technology Assessment Critical Minerals Status, Challenges and Policy Options for Recovery from Nontraditional Sources,”3 illustrates the widespread use of critical minerals in five key industry sectors: aerospace, defense, energy, telecommunications and electronics, and transportation. Figure 2 also shows the U.S. import reliance for each mineral and the countries that are the primary sources of these minerals. This comprehensive compilation of critical minerals information paints a compelling picture of the foundational role that minerals play in modern society and the U.S.’ current dependency on foreign countries to supply these minerals.

The need for minerals in the defense sector is perhaps the most troubling aspect of our foreign minerals and materials reliance. In a 2023 report, the Department of Defense (DOD) estimated that in a national emergency scenario, which is defined as a conventional armed conflict with China, the military would face shortfalls for 69 minerals, 20 of which are primarily procured from China.4

The country’s mineral demand shown in Figure 2 is just part of the story because minerals and materials are needed for all other industry sectors (e.g., manufacturing, technology, agriculture, etc.) The undisputably crucial need for minerals and materials underscores the urgent need for a Director and a federal entity like the NMMC to provide executive and legislative branch policymakers with accurate and timely minerals and materials information and advice, to perform and manage research efforts to increase and enhance domestic mining and mineral processing capabilities, and to help federal regulators with technical issues during the mine permitting process.

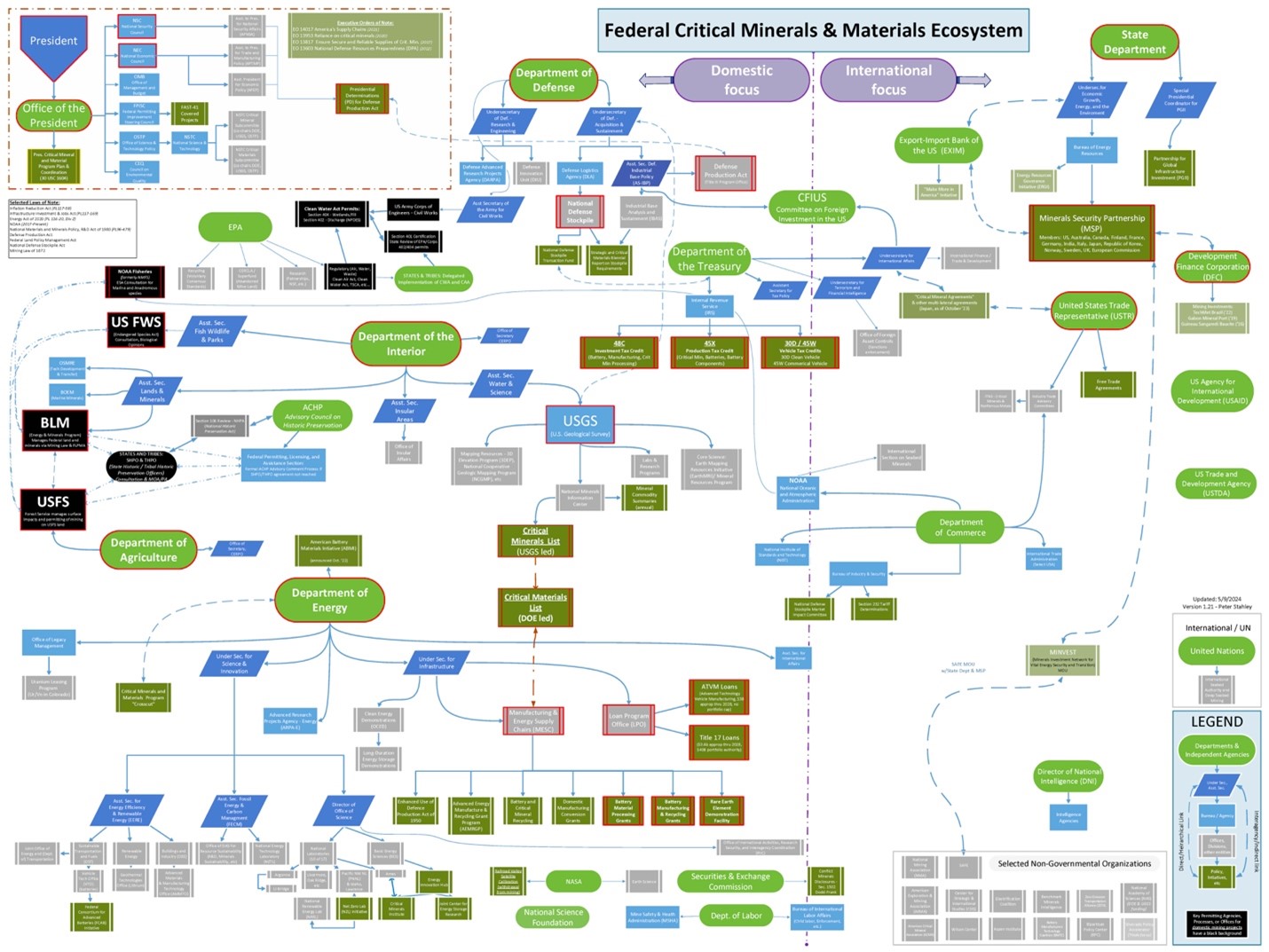

With an increasing number of technologies reliant on minerals, the demand for minerals has also increased exponentially as has the number of government agencies involved with mineral supply chains. The lack of a centralized agency has created confusion in a number of areas within the federal government. Figure 3 illustrates the many government agencies that have some touch point throughout the domestic critical minerals and minerals ecosystem. Given the crucial uses of the minerals shown in Figure 2 and the DOD’s projected shortfall of minerals and materials the military needs to defend the Nation, it is risky and unwise to rely on this bureaucratic maze of departments and agencies to ensure the availability of minerals and materials. The NMMC is needed to forge a path through this maze to seek synergy, consistency, and efficiency and to minimize inconsistent policies, duplication of efforts and obstacles to mineral development.

The absence of federal research in the areas of mining and mineral processing has also had far-reaching implications to the mining industry’s workforce and its education stream. There are currently just 14 universities that offer undergraduate programs in mining and metallurgy in the U.S. compared to 20 in 1995 and 25 in 1982.

According to the Center for Strategic & International Studies, “More than half the current domestic mining workforce will need to be retired and replaced by 2029 (roughly 221,000 workers). This number stands in stark contrast to the total of just 327 degrees awarded in 2020 in mining and mineral engineering and a 39 percent net drop in graduations in the U.S. since 2016. University programs tasked with creating this workforce have also been decreasing, with the number of mining and mineral engineering programs in the U.S. dropping from 25 in 1982 to 14 15 in 2023. This is in stark contrast to China, which has over 38 mineral processing schools and upwards of 44 mining engineering programs. Central South University, China’s largest mineral processing program, has 1,000 undergraduates and 500 graduate students alone ready to accomplish China’s mineral ambitions.5

3. Why the U.S. Needs an Entity Coordinating Federal Minerals Research

Meeting the Skyrocketing Mineral Demand will Require Federal Minerals Research

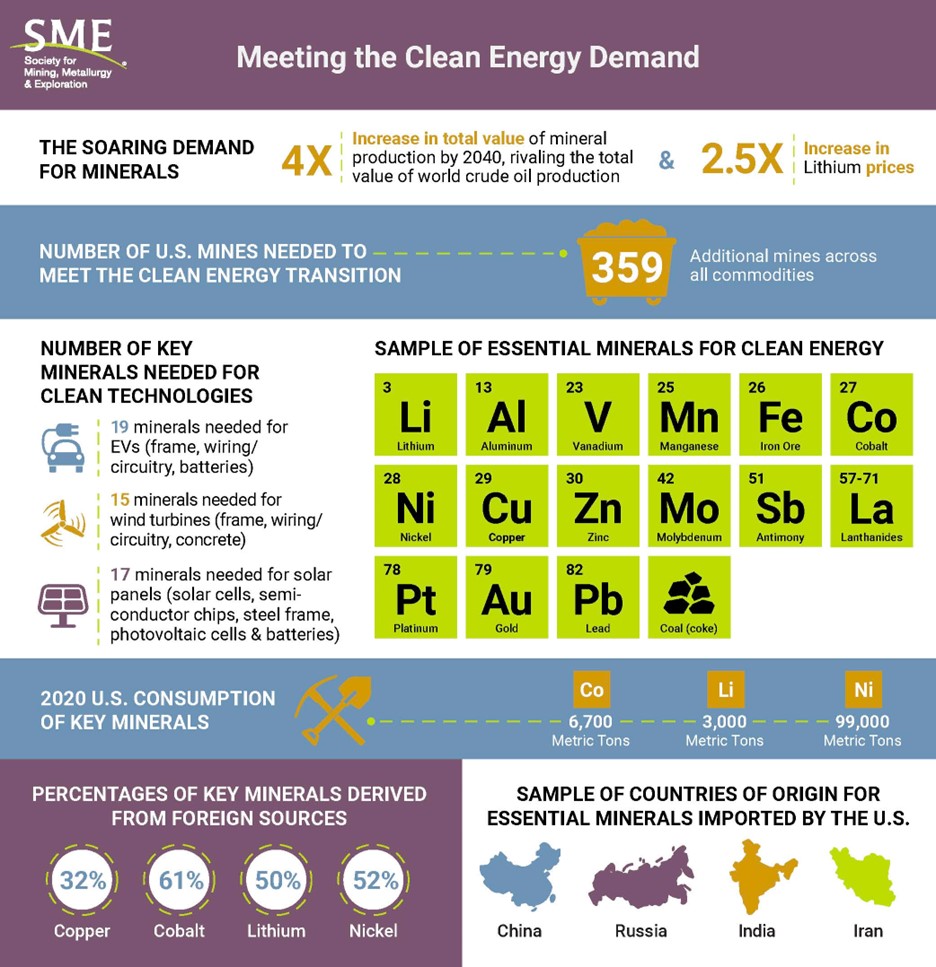

Figure 4 shows SME’s 2023 estimate that the U.S. must develop 359 new domestic mines to provide the minerals needed for electric vehicles, wind turbines, solar panels, transmission lines and the other infrastructure that must be built to achieve clean energy transition objectives. This transition will require a broad spectrum of minerals including copper, cobalt, lithium, and nickel. However, as shown on Figure 4, the U.S. imports 32 percent of the copper, 61 percent of the cobalt, 50 percent of the lithium, and 52 percent of the nickel that the U.S. needs. Some of these minerals are imported from adversarial countries like China and Russia or from countries like Indonesia where some mines do not use appropriate environmental or mine worker health and safety safeguards.

The absence of federal minerals research has caused the U.S. to fall behind the rest of the world during one of the most transformative times in human history. As the world looks to transition to a clean energy economy, global demand for minerals is set to skyrocket by 400 to 600 percent over the next several decades. For minerals such as lithium and graphite used in electric vehicle (EV) batteries, demand will increase by even more — as much as 4,000 percent.6

According to the International Energy Agency (IEA), the demand for electricity to power artificial intelligence (AI) applications and for the information exchange will also continue to increase.

“Electricity consumption from data centers, artificial intelligence (AI) and the cryptocurrency sector could double by 2026. Data centers are significant drivers of growth in electricity demand in many regions. After globally consuming an estimated 460 terawatt-hours (TWh) in 2022, data centers’ total electricity consumption could reach more than 1,000 TWh in 2026. This demand is roughly equivalent to the electricity consumption of Japan. Updated regulations and technological improvements, including on efficiency, will be crucial to moderate the surge in energy consumption from data centers.”7

The USBM’s research duties that Congress established in 30 U.S.C § 3 are urgently needed today to address the country’s dangerous reliance on foreign minerals:

“It shall be the province and duty of the United States Bureau of Mines ... to conduct inquiries and scientific and technologic investigations concerning mining, and the preparation, treatment, and utilization of mineral substances with a view to improving health conditions, and increasing safety, efficiency, economic development, and conserving resources through the prevention of waste in the mining, quarrying, metallurgical, and other mineral industries; to inquire into the economic conditions affecting these industries; to investigate explosives and peat; and on behalf of the Government to investigate the mineral fuels and unfinished mineral products belonging to, or for the use of, the United States, with a view to their most efficient mining, preparation, treatment, and use; and to disseminate information concerning these subjects...”

Currently, many of the research topics listed in 30 U.S.C. § 3 are an unfunded mandate that Congress needs to address immediately in conjunction with its appropriations to support clean energy transition goals, including recovering minerals from legacy mine wastes, batteries, and recycled e-waste, all of which require mining, metallurgical, and mineral processing expertise. With appropriate funding, the NMMC could play a pivotal role in improving processes to recover minerals from mine wastes and enhance recycling of minerals from e-wastes. These are examples of broadly applicable, cutting-edge, and transformative research that individual companies are unlikely to undertake because private-sector research efforts are typically more narrowly tailored to focus on a specific project or e-waste stream.

Congress has Appropriated Trillions to Support Critical Minerals Projects

In the Bipartisan Infrastructure Law (BIL) of 2021, the Inflation Reduction Act of 2022, the Chips and Science Act of 2022, and the FY 2023 National Defense Authorization Act (NDAA), Congress has appropriated trillions of dollars of funding for critical minerals projects.8 Examples of recent appropriations include:

- $858 billion in the FY 2023 NDAA for development of a Federal strategy to recycle and recover critical minerals from batteries used in the Federal electric vehicle fleet.

- $3 billion in Section 40704 of the BIL to “establish a program to inventory, assess, decommission, reclaim, respond to hazardous substance releases, and remediate abandoned hardrock mine land based on conditions including need, public health and safety, potential environmental harm, and other land use priorities,” with 50 percent for grants to states and tribes with jurisdiction over reclaiming abandoned hardrock mine land and remediating impacted waters, and 50 percent to the Secretary of the Interior for use on federal lands.

- $100 million in the BIL Section 40210 grant program for each of fiscal years 2021 through 2024 for critical minerals mining and recycling research grants to academia and the private sector for pilot projects for processing or recycling domestic critical minerals and developing U.S. critical minerals and metals. These grants are to focus on secondary recovery of critical minerals and metals from discarded end-use products or from waste products produced during the metal refining and manufacturing process, including from mine waste piles, acid mine drainage sludge, or byproducts produced through legacy mining and metallurgy activities, and to advance critical mineral processing research activities to improve separation, alloying, manufacturing, or recycling techniques and technologies that can decrease the energy intensity, waste, potential environmental impact, and costs of those activities. (To date, Congress has not appropriated the funds to implement this grant program.)

- $5 billion in conditional loan commitments for domestic critical minerals projects authorized by DOE’s Loan Program Office.9

- $6 billion in Section 40207 of the BIL to support grants for demonstration and commercial facilities associated with Battery Materials Processing and Battery Manufacturing.

Although there is some expertise in DOE, DOI, and DOD and other federal agencies on critical minerals and some cross-agency coordination, there is no centralized federal agency like the USBM with the expertise to provide the leadership necessary to effectively conduct, direct, and coordinate federally-funded critical minerals R&D projects. Consequently, Congress’ recent critical minerals appropriations functionally outsource many mineral processing, recycling and other important critical minerals research topics to academia and the private sector with relatively little federal supervision and coordination. Additionally, there is no technical group that can readily help Congress fulfill its oversight obligations to ensure that expenditures of taxpayer monies on critical minerals projects are achieving their intended purposes.

4. Federal Minerals and Mining Research – Then and Now

During the SME Roundtable, the Experts agreed that in the absence of the USBM, Congress has had to rely on universities and companies to perform some of the mineral research functions for which the USBM was formerly responsible. Academic and private-sector research efforts could be greatly enhanced by technical input, guidance, and coordination from a reinvigorated federal minerals entity.

The USBM was the primary federal agency conducting scientific research and disseminating information on the extraction, processing, use, and conservation of mineral resources. The Roundtable Experts emphasized the importance of the USBM’s technology transfer responsibilities and its role in stimulating new, enhanced, and safer mining and mineral processing operations. This stands in marked contrast to the current situation in which the recipients of federal critical minerals grants and loans are often conducting proprietary research that is not designed to quickly benefit other private-sector companies. Although the results of most federally-funded R&D projects (except for DOD-funded efforts) eventually go into the public domain, there is typically a one to five year waiting period before the research results are released to give academic entities the opportunity to publish their findings or to provide the companies that successfully develop new technologies a temporary proprietary advantage.

The USBM’s substantial contributions to improving miner health and safety through its research programs was discussed during the Roundtable. When the USBM was defunded, its health and safety research functions were transferred to the National Institute for Occupational Health and Safety (NIOSH), which is part of the Centers for Disease Control and Prevention (CDC), in the Department of Health and Human Services (DHHS). Roundtable participants with first-hand experience with NIOSH stated that the CDC is not the optimal federal agency for mining health and safety research because of the unique workplace issues at surface and underground mines, and the much broader focus of the CDC. The group agreed that it is important for future mining health and safety research to be performed in an entity whose primary focus is on mining.

Another important aspect of the USBM discussed during the Roundtable was USBM’s history of developing new mineral processing technologies that have made significant economic contributions. The Roundtable Experts with direct knowledge of some of these contributions pointed to the USBM’s pivotal role in the late 1960s in developing the cyanide heap leach precious metals recovery technology that is now used globally to extract gold and silver from low-grade ores. In Nevada, the advent of heap leach technology built an entire gold mining industry that today has positioned Nevada as one of the world’s top gold-producing regions. Using the USBM’s research results, the world’s first commercial-scale gold heap leach facility began operating at the Cortez Gold Mine in Lander County, NV in 1971.10 Since then, gold mines in Nevada using heap leach technology have contributed many billions of dollars of tax revenues to federal, state and local governments, and have create many thousands of high-paying jobs.

The Experts focused on how similar applied research could evaluate techniques for recovering residual metals from tailings, waste rocks, and e-wastes and improve recoveries of certain minerals including but not limited to rare earths and lithium claystone deposits. For example, several Nevada-based companies seeking to develop lithium claystone deposits have either received or applied for DOE funding to build and test their mineral processing facilities. This is the type of research that a future NMMC could perform and/or coordinate with private-sector or academic researchers to develop processing technologies to optimize lithium recovery that could have broader applicability to this newly discovered type of lithium deposit compared to the current DOE-funded research efforts that are focusing on each company’s project-specific deposit. The USBM’s heap leach technology development and the need for lithium claystone processing optimization are examples of non-proprietary, high-risk/high-reward research projects that private-sector interests are unlikely to pursue without government-funded assistance.DOE’s Office of Fossil Energy and Carbon Management (FECM) has recently received some limited funding to develop new advances in critical mineral mining and extraction technologies, but support for this type of research needs to be greatly expanded. Ideally, in creating the NMMC, Congress should provide adequate funding for future NMMC-led mining and mineral processing research. However, recognizing that funding will probably be limited, the NMMC could at first focus on coordinating and performing oversight of federally funded, third-party research being performed by private companies, academia, and the national laboratories. Ultimately, the best outcome would be for the NMMC to have adequate funding to perform targeted in-house research with the objective of discovering breakthrough technologies that have the potential to substantially improve mining and mineral processing and recycling. There can be no doubt that the substantial and multi-decades long economic benefits resulting from USBM’s heap leach technology development clearly demonstrate that federal investment in mining and mineral processing R&D can produce significant and long-term benefits for the public as well as for local, state, and federal governments. Besides creating positive economic and fiscal impacts, federal research to improve minerals mining, processing, and recycling methodologies would help achieve the National objective to increase domestic minerals production and reduce our reliance on foreign minerals.

5. The IWG Report Underscores the Need for a Federal Minerals Group

In its September 2023, report, the IWG found that:

“In order to cultivate an environment conducive to rebuilding the U.S. mining sector, the federal government needs to promote a stream of consistent and widely available geologic data, technology, and support infrastructure, as well as dedicated funding for mining science, metallurgy, and mining education. In recognition of the need for additional data, technology, research, and consistency, several commenters [to the IWG] recommended that the U.S. Bureau of Mines (USBM), or a similar single agency, be reestablished.” 11

As described in the IWG Report, the USBM’s mission included the following functions:

- Conducting scientific and technologic investigations concerning mining, and the preparation, treatment, and utilization of mineral substances with a view to improving health conditions, increasing safety, efficiency, economic development, and conserving resources through the prevention of waste in the mining, quarrying, metallurgical and other mineral industries;

- Inquiring into the economic conditions affecting these industries and investigating explosives and peat;

- Investigating the mineral fuels and unfinished mineral products belonging to, or for the use of, the United States, with a view to their most efficient mining, preparation, treatment, and use;

- Disseminating information concerning these subjects; and

- Researching the scientific basis for technology to help meet the Nation’s mineral and material needs and mitigate associated economic, human, and environmental costs.

A New Minerals Group Should be Responsible for Data Compilation and Management

The IWG Report describes the important role that the USBM played in compiling, distributing, and archiving mining and other technical data that are essential in identifying and developing the country’s mineral resources:

“The closure of the USBM resulted in the loss of a central Federal steward of USBM research and mining data repositories and inconsistent preservation and transfer of USBM data, maps, reports, and information (mostly in hardcopy or microfiche formats) to various successor agencies and the National Archives. The extent to which USBM data, maps, reports, and information have been preserved is unknown, which poses challenges to accessing USBM information. The USGS and a few other libraries are in the process of digitizing and placing online some historic USBM publications, most of which are not otherwise available except in physical copies and are at risk of being lost.12

The IWG Report states that: “Federal mining and mineral data are fragmented and incomplete” and specifically recommends building a federal database of mineral data that “is compiled in a unified format that is accessible and understandable to the public.”13 An important role for a future NMMC would be to fill this data collection and preservation gap. Although the IWG suggests that the BLM, the U.S. Forest Service, or the USGS could be charged with developing and maintaining this database, it would be more appropriate to assign this new function to a future NMMC given the USBM’s former role in maintaining mineral and mining data. Assigning this function to the federal land management agencies (e.g., the BLM and the U.S. Forest Service) would not be optimal because geology, mining, and mineral processing are outside of these agencies’ main areas of expertise. Similarly, the USGS is not the best choice for housing this database because its expertise mainly focuses on the geology of mineral deposits and does not extend to how to mine and process mineral deposits.

The IWG is not the only group that recognizes the country’s current shortcomings in compiling and maintaining geologic and mining data. According to the American Association of State Geologists, the U.S. lacks an effective process for gathering, organizing, compiling, or publicly sharing geologic data that would help in the identification of valuable mineral deposits.14

A New Minerals Group is Needed to Provide Technical Expertise to Regulators During the Mine Permitting Process

The IWG Report states that federal regulatory agencies require more mining technical expertise during the federal mine permitting process. The report describes the need for “a sustained focus on hiring, training, and retaining agency mining experts to expedite the environmental analyses and permitting needed to increase domestic critical mineral supplies, protect the environment, and engage interested Tribes and stakeholders.”15 The report explains that mining expertise is lacking at all of the federal agencies that prepare Environmental Assessments and Environmental Impact Statements as required by the National Environmental Policy Act (NEPA) to evaluate proposed mining projects.16

The IWG Report discusses agency staffing shortages and limited mining expertise as a key factor in the protracted permitting process, referencing a GAO study that identified a shortage of agency resources, including “staff, staff expertise, funding, infrastructure, training, and/or computer technology,” as the second most cited challenge affecting the hardrock mine plan review process. Similarly, the IWG Report also cites a 1999 National Research Council report that identified staffing shortages at some land management offices: “Offices responsible for regulating mine projects may not always have access to the trained and experienced personnel required.” 17

The IWG recommends that Congress provide sufficient support to Federal agencies to hire, train,

and retain experts in mining, mining engineering, environmental science, environmental engineering, project permitting, and related fields, and that Federal experts in these areas be dedicated to evaluating and monitoring mineral exploration, mine plans, designs and operations, environmental analysis, reviewing environmental monitoring and remediation plans, and monitoring and overseeing compliance with mining and environmental requirements and permitting-related work.18

The Roundtable Experts recommend that this expertise should be developed in a new centralized mineral entity like the NMMC that could provide technical expertise as needed to federal regulatory agencies during the mine permitting process. Focusing this expertise in the NMMC rather than scattering it across departments and among the federal regulatory agencies would be the most cost effective way to provide high-caliber mining technical advice to federal regulators. Centralizing this expertise would have the added advantage of ensuring a consistent approach between the various federal regulatory agencies with jurisdiction over proposed mining projects. It would also give federal regulators located in areas with few mining projects and little familiarity with mining issues ready access to mining expertise.

The IWG Report Recommendations for Mining Research Topics

The IWG Report states that with the demise of the USBM, “Federal research and development support in fields such as mining, environmental science and technology, and minerals and materials sciences has been lost”19 and recommends reestablishing these research efforts. Table 1 lists the IWG’s recommendations for future research to improve mining and mineral processing and to minimize the environmental impacts associated with mining.

|

As explained in the IWG Report, reestablishing the former USBM’s role in technology transfer could improve the implementation of research into practice and advance improved technologies throughout the entire mining life cycle. Investments in both data collection and research will also allow for the professional development of a new generation of subject matter experts whose knowledge can support efforts to modernize the mining and permitting systems in the U.S.21

6. The Roundtable’s Recommendations for NMMC Minerals Research

Research is needed to improve almost every aspect of the materials production cycle including: extracting minerals; enhancing materials performance; increasing mineral recoveries; reducing energy consumption in mining and mineral processing operations; pursuing waste management technologies and resource conservation; ensuring the health and safety of the workers in the Nation’s mines and mineral processing plants; and minimizing and mitigating the environmental impacts of mining and mineral processing.

One of the key areas of research that the NMMC could pursue would be to develop technologies to improve mining and processing of lower-grade ores. This is important because the average grades of most recent mineral discoveries has decreased compared to past discoveries. For example, the standard cutoff grade for a copper deposit in 1995 was about 2 percent. Today, it is roughly 0.1 percent.22 This decrease in ore grades means that larger volumes of ore must be processed to recover the valuable metal, which increases costs due to increased energy consumption to mine and handle larger volumes of ore and waste rock and to process the lower grade ores.

Additionally, in many lower grade ore deposits, the target metal(s) are very fine-grained and may be encapsulated within gangue materials or embedded in the host rocks. These ores require more crushing, grinding, and separation (i.e.; comminution) than coarser ores. Because comminution costs amount to between 35 and 50 percent of total mine costs,23 research on comminution technologies to reduce the amount of energy required to process fine-grained, lower grade ores could improve overall mine economics. Research to improve recoveries from low-grade deposits and to reduce mining costs could make more deposits economically viable to mine and play a significant role in helping meet the future demand for minerals. This research could also be applicable to recovering residual metals in legacy waste rocks and tailings, potentially reducing the environmental footprint of mining by reclaiming legacy sites that were mined prior to the enactment of modern environmental regulations and reclamation requirements.

The Experts agreed that many of the essential research functions of the USBM need to be refunded and that the NMMC should be responsible for:

- Serving as a trusted, unbiased and fact-based advisor to Congress and Executive Branch officials to help them develop U.S. mineral policies to reduce the Nation’s reliance on imported minerals from adversarial countries and strengthen domestic mineral production and supply chains;

- Ore treatment research focused on the processing and subsequent handling of ore materials to find the most economically viable extraction processes and to identify any health and safety hazards associated with these processes;

- Research programs to improve the metals security of America by researching technology that would promote efficient and profitable mining while improving environmental performance and worker health and safety;

- Testing and surveying areas with minerals of economic interest;

- Research to identify extractive metallurgical technologies to reduce environmental impacts from mine waste management facilities and to characterize and clean up old mine sites with metals contamination;

- Development of waste minimization and recycling technologies to recycle mineral processing operation byproducts including scrap, residues, and effluents;

- Research collaboration between the federal government, industry and academia;

- Elevating policymakers’ and the general public’s understanding of the importance of mining and minerals;

- Providing guidelines to streamline the permitting process;

- Reducing comminution energy demands;

- Improving sorting technology;

- Reducing energy consumption for comminution, autoclave smelting, and low-temperature autoclaves;

- Working with the DOE’s FECM office on Carbon Capture Utilization and Sequestration technologies; and

- Mineral economics and forecasting.

7. The U.S. Needs a Federal Minerals Entity to Compete on the World’s Stage

During the May 30th Roundtable, the contrast was drawn between the U.S., which does not have a governmental entity that serves as a “Minister of Mines,” and the numerous other countries that do have such a position. The governments of Australia, Canada, and Mexico, three important sources of minerals for the U.S., have high-ranking mining departments and officials called “Ministers”. According to Wikipedia, 29 countries have a Minister of Mines or an equivalent government official as listed in Table 2.24

|

Table 2: Wikipedia List of Countries with Ministers of Mines |

|

|

Afghanistan |

Mauritania |

An overlapping but different list of 34 countries is shown in Table 3 adapted from the Mineral Development Network Platform’s website, which lists the countries as having a mining authority, Minister of Mines or the functional equivalent.25

|

Table 3 |

||

|

European Union Member States |

Latin America |

|

|

|

|

It is immediately obvious from Tables 2 and 3 that the U.S. is an anomaly because it does not have a centralized mining authority or Minister of Mines. There can be no doubt that not having such an entity puts the U.S. at a distinct disadvantage compared to many other countries. Given the soaring demand for minerals and the growing concerns about the Nation’s dangerous reliance on foreign adversaries for many of the minerals we need for national defense, a strong economy, manufacturing, infrastructure, and the energy transition, it makes no sense to handicap our country by not having a federal entity like the proposed NMMC to make mining in the U.S. competitive with other countries. Additionally, the concept of “friendshoring” our mineral supplies from countries with which we have solid trade relationships is not a panacea because those nations need their minerals to support their economies, militaries, industries, and energy transition plans. Consequently, they may not always be in a position to sell their minerals to the U.S. when we need them.

8. Critical Materials and Critical Minerals Legislative History Overview

The National Materials and Minerals Policy, Research and Development Act of 1980

In order to evaluate options for creating the Director and the NMMC and ensuring that they will be responsible for both critical materials and critical minerals, it is important to understand the legislative histories and evolution of the terms “materials,” “minerals,” “critical materials,” and “critical minerals.” The National Materials and Minerals Policy, Research and Development Act of 1980 (“the 1980 Act”)26 establishes a national policy for materials in order to strengthen the materials research, development production capability and performance of the U.S. The 1980 Act’s definition of materials includes minerals:

“The term “materials” means substances, including minerals, of current or potential use that will be needed to supply the industrial, military, and essential civilian needs of the United States in the production of goods or services, including those which are primarily imported or for which there is a prospect of shortages or uncertain supply, or which present opportunities in terms of new physical properties, use, recycling, disposal or substitution, with the exclusion of food and of energy fuels used as such.” 30 U.S.C. § 1601(b)(2)

Thus, since 1980, U.S. law has defined minerals as a subset of materials.

Definitions of Critical Materials and Critical Minerals

The Energy Act of 2020 amends the 1980 Act by adding Section 106, which defines critical materials and critical minerals, and splits the jurisdiction for the two between the DOE and the DOI. The DOE Secretary has jurisdiction over critical materials; the DOI Secretary is responsible for critical minerals. The Energy Act of 2020 establishes the following definitions for critical minerals and critical materials:

Critical material is defined at 30 U.S.C. § 1606(a)(2) to mean:

(A) any non-fuel mineral, element, substance, or material that the Secretary of Energy determines—

(i) has a high risk of a supply chain disruption; and

(ii) serves an essential function in 1 or more energy technologies, including technologies that produce, transmit, store, and conserve energy; or

(B) a critical mineral.

Critical mineral is defined at 30 U.S.C. § 1606(a)(3) to mean:

(A) In general any mineral, element, substance or material designated as critical by the Secretary [of the Interior] under subsection (c)

(B) Exclusions – the term critical minerals does not include

(i) fuel minerals;

(ii) water, ice, or snow;

(iii) common varieties of sand, gravel, stone, pumice, cinders, and clay.

30 U.S.C. § 1606(c) directs the DOI Secretary, acting through the Director of the USGS, to develop a critical minerals list that includes critical minerals recovered as byproducts from a host mineral. The Energy Act of 2020 similarly authorizes the DOE Secretary to establish the Critical Materials Research, Development, Demonstration and Commercialization Program and to establish a Critical Materials List that focuses on the materials that are critical for clean energy technologies.27 There is some overlap between DOI’s Critical Minerals List and DOE’s Critical Materials List.

The distinction between critical materials and critical minerals can become politically controversial as demonstrated during the recent legislative dialogue on H.R. 8446 to amend the Energy Act of 2020 to include critical materials in the definition of critical minerals. Congressman, Juan Ciscomani (R-AZ), introduced H.R. 8446. Congressmen Dan Newhouse (R-WA), and Elijah Crane (R-AZ) have cosponsored this bill. During the June 4, 2024 hearing before the House Subcommittee on Energy and Mineral Resources, several Democrats vociferously opposed H.R. 8446, alleging it was an attempt by the mining industry to benefit financially by making more minerals (specifically copper) eligible for DOE and DOD critical minerals grants and loans.28

Mr. Misael Cabrera’s testimony in support of H.R. 8446 at this hearing explains the importance of placing equal emphasis on both critical materials and critical minerals: “H.R. 8466 ... recognizes that critical minerals and materials designations are complementary in nature and that federal funding should flow to support research, development, and deployment efforts across both domains. By doing so, the United States can strengthen its resilience to supply disruptions and continue to lead in energy innovation and environmental stewardship.”29

9. Creating a National Minerals and Materials Council within the Executive Office of the President’s National Economic Council

The statutorily bifurcated definitions of and jurisdictions for critical materials versus critical minerals is not optimal for addressing the universe of materials and minerals needed for all aspects of our economy, society, and national defense. The ongoing debate over excluding copper from the USGS’ critical minerals list versus its inclusion in the DOE’s critical materials list is a case in point. These distinctions and separations have the potential to create a turf war between DOI and DOE that can be avoided by placing the Director and the NMMC within the NEC in order to clearly give them responsibility for both critical materials and critical minerals. The NEC is the ideal location within the EOP to ensure equitable consideration of both critical materials and critical minerals and to coordinate directly with both DOE and DOI pursuant to the roles the Energy Act of 2020 establishes for both departments. Because mining is at the front end of every supply chain overseen by the NEC including infrastructure, manufacturing, housing, and technology and innovation, domiciling the Director and the NMMC in the NEC is the best place to achieve inter-departmental synergies and consistency, and facilitate the participation of other cabinet-level executive departments with a direct interest in materials and minerals supply chains including, but not limited, to the Departments of Defense, Commerce, and State.

To achieve its purpose, the NMMC needs to employ a wide range of policy and technical professionals with mining, mineral processing, mineral economics, geological, environmental, regulatory, health and safety, and legal expertise. These experts should be recruited from the private sector, federal agencies currently involved with mineral issues, and academia. Some of the recruits who are already employees of other federal agencies may be able to retain some of their existing duties with a dotted line position with the NMMC that allow them to split their times between their original agency and the NMMC.

The complex web of agencies and departments with some responsibility for critical minerals and materials shown in Figure 3 also illustrates why placing the NMMC in the NEC would be an effective way to rationalize and navigate through this maze. As part of the NEC, the Director and NMMC would be optimally positioned to take a whole-of-government approach that would go far beyond the DOI/Bureau of Land Management’s role in managing the 700 million-acre federal subsurface mineral estate and the 254 million acres of the surface of public lands30 or the DOE’s involvement with the critical materials loan and grant programs authorized in the BIL.31

Although it is not possible at this point to know how much the NMMC would cost, the costs to establish and fund a future NMMC would obviously depend on the scope of work established for this new entity. A big factor in determining the level of funding needed would be whether the NMMC’s portfolio includes performing in-house research and setting up or re-establishing one or more research facility similar to the USBM’s regional research centers. As discussed above, the NMMC would ideally be provided with sufficient funding to support in-house research. To minimize costs, much of this research could be performed at national laboratories, universities, or at private-sector facilities rather than at new or re-established research centers. Another lower cost option would be for the NMMC to focus mainly on managing and evaluating DOE, DOD, and other federally funded research projects conducted by the national laboratories, academia, and the private sector.

As an order of magnitude estimate, it is useful to look at some available cost data for the former USBM. In 1994, the National Academy of Sciences (NAS) conducted a study of the USBM that includes the following information about the costs allocated to three of the USBM’s functions for FY 1994:32

- Health, Safety and Mining Technology - $52 million

- Minerals and Materials Sciences - $25 million

- Environmental Technology - $21 million

According to J. Daniel Harrison’s paper entitled ”The Circumstances, Events and Politics Leading to the Closure of the U.S. Bureau of Mines – Was it the Correct Decision“ published in the April 2010 edition of Mining Engineering,33 Congress appropriated $152.4 million to fund the USBM in FY 1995

10. The Bipartisan Infrastructure Law Already Authorizes Many of the Functions of the Former U.S. Bureau of Mines

The BIL could potentially be interpreted as creating the statutory basis for establishing the NMMC as a new federal entity charged with performing some of the R&D functions of the former USBM. Section 40210 of the BIL, entitled “Critical Minerals Mining and Recycling Research,” describes research topics that align with many of the mining, mineral processing, and recycling R&D programs that the USBM used to perform.

The BIL Section 40210(b), “Critical Minerals Mining and Recycling Research and Development,” establishes a competitive awards program that outsources minerals R&D to universities, the national laboratories, nonprofit organizations, and the private sector to “support basic research that will accelerate innovation to advance critical minerals mining, recycling and reclamation strategies and technologies...to make better use of domestic resources and to eliminate national reliance on mined minerals and mineral materials that are subject to supply disruptions.”

Awards pursuant to Section 40210(b) are to be used to accomplish the following objectives:

- Advance mining research and development activities to develop new mapping and mining technologies and techniques, including advanced critical mineral extraction and production to:

- Improve existing, or to develop new, supply chains of critical minerals; and

- Yield more efficient, economical, and environmentally benign mining practices;

- Advance critical mineral processing research activities to improve separation, alloying, manufacturing, or recycling techniques and technologies that can decrease the energy intensity, waste, potential environmental impact, and costs of those activities;

- Advance research and development of critical minerals mining and recycling technologies that take into account the potential end-uses and disposal of critical minerals, in order to improve end-to-end integration of mining and technological applications;

- Conduct long-term earth observation of reclaimed mine sites, including the study of the evolution of microbial diversity at those sites;

- Examine the application of artificial intelligence for geological exploration of critical minerals, including what size and diversity of data sets would be required;

- Examine the application of machine learning for detection and sorting of critical minerals, including what size and diversity of data sets would be required;

- Conduct detailed isotope studies of critical minerals and the development of more refined geologic models; and

- Provide training and research opportunities to undergraduate and graduate students to prepare the next generation of mining engineers and researchers.

Many if not all of the above-listed functions are similar to the mining and mineral processing R&D mission of the former USBM and include the types of research that the NMMC should undertake either directly and/or in collaboration with academia and the private sector. Similarly, many of these functions touch on worker health and safety, which was a primary focus of the USBM. This critically important function should be assigned to a mining-focused group rather than to the CDC whose primary mission does not include mine worker health and safety.

The BIL Section 40210(c) creates the Interagency Subcommittee on Critical Minerals (CMS), within the EOP as a multi-department entity within the National Science and Technology Council (NSTC) and co-chaired by the DOE, DOI, and the Office of Science and Technology Policy (OSTP). However, Section 40210(c) does not effectively overcome the distinction between critical materials and critical minerals created in Section 1606 of the Energy Act of 2020 because it only references critical minerals and does not mention critical materials. As discussed below, future legislation should change the name “CMS” to “NMMC,” relocate the NMMC to the NEC, and explicitly state that the NMMC has responsibility for both critical minerals and critical materials.34

As described in Section 40210(c), the purpose and duties of the CMS are to:

- Support supply chain resiliency and coordinate Federal science and technology efforts to ensure secure and reliable supplies of critical minerals to the United States.

- Advise and assist the NSTC, including the Committee on Homeland and National Security of the NTSC, on U.S. policies, procedures, and plans relating to critical minerals, including:

- Federal research, development, and deployment efforts to optimize methods for extractions, concentration, separation, and purification of conventional, secondary, and unconventional sources of critical minerals, including research that prioritizes end-to-end integration of mining and recycling techniques and the end-use target for critical minerals;

- Efficient use and reuse of critical minerals, including recycling technologies for critical minerals and the reclamation of critical minerals from components, such as spent batteries;

- Addressing the technology transitions between research or lab-scale mining and recycling and commercialization of these technologies;

- The critical minerals workforce of the United States; and

- U.S. private industry investments in innovation and technology transfer from federally funded science and technology;

- Identify emerging opportunities, stimulate international cooperation, and foster the development of secure and reliable supply chains of critical minerals, including activities relating to the reuse of critical minerals via recycling;

- Ensure the transparency of information and data related to critical minerals; and

- Provide recommendations on coordination and collaboration among the research, development, and deployment programs and activities of Federal agencies to promote a secure and reliable supply of critical minerals necessary to maintain national security, economic well-being, and industrial production.

Sections 40210(c)(3) and (4) establish the following discretionary and mandatory responsibilities of the CMS:

Discretionary Responsibilities:

- Provide recommendations on how Federal agencies may improve the topographic, geologic, and geophysical mapping of the United States and improve the discoverability, accessibility, and usability of the resulting and existing data, to the extent permitted by law and subject to appropriate limitation for purposes of privacy and security;

- Assess the progress toward developing critical minerals recycling and reprocessing technologies;

- Assess the end-to-end lifecycle of critical minerals, including for mining, usage, recycling, and end-use material and technology requirements;

- Examine, and provide recommendations for, options for accessing and developing critical minerals through investment and trade with allies and partners of the United States;

- Evaluate and provide recommendations to incentivize the development and use of advances in science and technology in the private industry;

- Assess the need for, and make recommendations to address, the challenges the United States critical minerals supply chain workforce faces, including:

- Aging and retiring personnel and faculty;

- Public perceptions about the nature of mining and mineral processing; and

- Foreign competition for United States talent;

- Develop, and update as necessary, a strategic plan to guide Federal programs and activities to enhance:

- Scientific and technical capabilities across critical mineral supply chains, including a roadmap that identifies key research and development needs and coordinate ongoing activities for source diversification, more efficient use, recycling, and substitution for critical minerals; and

- Cross-cutting mining science, data science techniques, materials science, manufacturing science and engineering, computational modeling, and environmental health and safety research and development; and

- Report to the appropriate committees of Congress on activities and findings under this subsection.

Mandatory responsibilities

- Identify and evaluate Federal policies and regulations that restrict the mining of critical minerals.35

As an interagency subcommittee, the CMS has broad participation across the federal government, with the OSTP, DOE, and the USGS serving as the CMS co-chairs. The interagency/interdepartmental structure of the CMS clearly establishes CMS’ whole-of-government charter that acknowledges the extensive footprint of material and mineral issues across the federal government. The CMS member agencies include the Departments of Agriculture, Commerce, Defense, Education, Energy, Homeland Security, Interior, and Labor.36

The activities page on the CMS website summarizes its key issues as follows: 37

- Research and Development

- Strengthen Supply Chains

- International Engagement

- Map and Quantify Domestic Resources

- Permitting and Standards

- Education and Workforce Development

Taken together, the R&D functions in Section 40210(b) and the responsibilities described in Section 40210(c) capture a significant portion of the former USBM’s mission, with the notable exception and key issue of mine worker health and safety. In response to the current concerns about the Nation’s dangerous dependency on mineral imports, Section 40210(c) also includes directives pertaining to permitting, reducing the Nation’s reliance on foreign minerals, and strengthening domestic mineral supply chains. Therefore, a key question to ask is:

Could an advocacy campaign to reestablish many of the functions of the former USBM capitalize on Section 40210(c) of the BIL to assert that in establishing the CMS, Congress has already created the functional equivalent of the USBM but has not appropriated funds for it to operate?

Rather than starting from scratch to enact legislation to authorize “a new USBM,” it may be more strategic to consider how Congress could amend Section 40210(c) of the BIL to accomplish the following objectives:

- Clarify that the CMS was created to fulfill many of the research and advisory functions of the former USBM;

- Elevate the status of the CMS by creating a Director the NMMC as part of the NEC because the cross-cutting and essential role of minerals across the federal government dictates that the NMMC must operate from a top-level EOP office like NEC rather than as part of the DOI where the former USBM was housed;

- Make the NMMC explicitly responsible for materials in addition to minerals, as these terms are defined in the 1980 Act, and for critical materials and critical minerals, as defined in the Energy Policy Act of 2020; and

- Create the process for adding an annual appropriation to the federal budget to fund the NMMC.38

11. Summary of the Roundtable’s Findings

The Roundtable of 18 mining technical and policy experts convened by SME determined that the U.S. should establish a federal entity that provides technical input and policy advice on domestic minerals and materials to Congress and Executive Branch agencies and departments. As described in this concept paper, this Roundtable recommends that a National Materials and Minerals Council (NMMC), led by a Director of Minerals, be established within the Executive Office of the President’s National Economic Council (NEC). The Director and the NMMC would be charged with providing a whole-of-government approach to the oversight of materials and minerals in coordination with all cabinet-level executive offices and their respective departments and agencies.

The NMMC would fill the void left by the 1996 Congressional action to defund the former U.S. Bureau of Mines. That decision has rendered the U.S. unable to mine or process many of the 50 minerals deemed “critical” by the U.S. Geological Survey (USGS). In 2023, the U.S. was 100 percent reliant on foreign sources for 15 of these minerals and 50 percent or more reliant on other countries for another 34 minerals (See Figure 1). Furthermore, as shown on Figure 2, the U.S. is dangerously dependent on China and other adversarial countries for minerals that are essential for the defense, energy, aerospace, electronics, telecommunications, and transportation sectors. For some minerals, the U.S. currently imports minerals from countries with inferior environmental protection and labor safety standards.

The Nation’s current lack of a centralized federal entity to oversee mineral and mining policies has produced an inefficient proliferation of federal agencies involved with minerals, as shown in the bureaucratic maze on Figure 3. Consequently, the U.S. is at a distinct disadvantage compared to many other nations that have a centralized and dedicated minerals group. The proposed NMMC would help the U.S. become more competitive with other countries.

The current inefficiencies and the resulting increased reliance on foreign minerals come at a time of rapidly increasing demand for numerous minerals for electric vehicles, wind turbines, transmission lines and other infrastructure. As shown on Figure 4, the SME estimates that the U.S. must develop 359 new domestic mines to meet the projected mineral demand of the coming decades.

The U.S. government has recently recognized the need for more minerals. Since 2021, Congress has appropriated trillions of dollars to support critical minerals. The Bipartisan Infrastructure Law of 2021, the Inflation Reduction Act of 2022, the CHIPS and Science Act of 2022 and the FY 2023 National Defense Authorization Act have appropriated funding of domestic critical mineral projects. But because the U.S. lacks a centralized agency such as the proposed NMMC, these appropriations functionally outsource much of the mineral processing, recycling, and other important critical minerals research topics to academia and the private sector without much technical oversight or a well-coordinated structure to keep track of these activities.

As noted on Page 90 in the 2023 IWG Report “Recommendations to Improve Mining on Public Lands”: “in order to cultivate an environment conducive to rebuilding the U.S. mining sector, the federal government needs to promote a stream of consistent and widely available geologic data, technology and support infrastructure, as well as dedicated funding for mining science, metallurgy and mining education.”

As envisioned by the Roundtable, the NMMC would serve as a trusted, unbiased and fact-based advisor to Congress and Executive Branch officials to help them develop U.S. mineral policies to reduce the Nation’s reliance on imported minerals from adversarial countries and to strengthen domestic mineral production and supply chains. The NMMC would also perform and supervise mineral research.

Placing the NMMC within the NEC reflects the importance of materials and minerals as the front-end supply chains for all sectors and governmental functions. As part of the NEC, the NMMC would be ideally situated to ensure consistency across multiple departments and agencies, reduce inefficiencies and duplication of efforts, and facilitate the participation of and coordination with cabinet-level executive departments with direct interest in materials and mineral supply chains including the Departments of Defense, Commerce, State and others. Ultimately, the NMMC would help minimize barriers to mineral development as a critical first step in restoring the country’s former status as “the global leader in mining” as characterized in the IWG Report.

For more information please contact: sme@smenet.org or wearewmc@wmc-usa.org

References:

1. https://www.doi.gov/sites/doi.gov/files/mriwg-report-final-508.pdf

Other factors contributing to the dramatic increase in the Nation’s reliance on foreign minerals include: the amount of potentially mineralized lands that have been put off-limits to mining since 1995; the deterioration of the permitting process, which takes much longer and costs much more than in 1995; the increased frequency of litigation challenging agency permitting decisions, thereby increasing permitting risks; the steady decline in the number of mining professionals graduating from U.S. mining schools; and cyclical metal prices. Back to content

2. Other factors contributing to the dramatic increase in the Nation’s reliance on foreign minerals include: the amount of potentially mineralized lands that have been put off-limits to mining since 1995; the deterioration of the permitting process, which takes much longer and costs much more than in 1995; the increased frequency of litigation challenging agency permitting decisions, thereby increasing permitting risks; the steady decline in the number of mining professionals graduating from U.S. mining schools; and cyclical metal prices. Back to content

Congressional Research Report, Emergency Access to Critical and Strategic Materials: The National Defense Stockpile, November 14, 2023, p. 9, https://crsreports.congress.gov/product/pdf/R/R47833, citing DOD, Strategic and Critical Materials 2023 Biennial Report on Stockpile Requirements, April 2023, p. 7. Back to content

4. Congressional Research Report, Emergency Access to Critical and Strategic Materials: The National Defense

Stockpile, November 14, 2023, p. 9, https://crsreports.congress.gov/product/pdf/R/R47833, citing DOD, Strategic and

Critical Materials 2023 Biennial Report on Stockpile Requirements, April 2023, p. 7. Back to content

5. (https://www.csis.org/analysis/united-states-needs-more-mining-engineers-solve-its-critical-mineral-challenges#:~:text=More%20than%20half%20the%20current,the%20United%20States%20since%202016) Back to content

6. Fact Sheet: Securing a Made in America Supply Chain for Critical Minerals (https://www.whitehouse.gov/briefing-room/statements-releases/2022/02/22/fact-sheet-securing-a-made-in-america-supply-chain-for-critical-minerals/) Back to content

8. The BIL is the largest appropriation, totaling $1.2 trillion to address climate change, which includes the need for critical minerals. It is important to note that there is very little funding to support critical minerals exploration and mining projects. Back to content

9. https://iea.blob.core.windows.net/assets/ee01701d-1d5c-4ba8-9df6-abeeac9de99a/GlobalCriticalMineralsOutlook2024.pdf, Page 228. Back to content

10. “In the 1960s the USBM was working on two parallel projects aimed at improving the recovery of lower-grade gold deposits. One trajectory was on the use of activated carbon as a cheaper alternative to the still-popular zinc dust recovery method, the latter commonly referred to as Merrill-Crowe. Another was on improved leaching, either in vats or in outdoor piles, called heaps.” https://www.mininghistoryassociation.org/Journal/MHJ-v28-2021-McQueen%20Heap%20Leaching%20in%20NV.pdf Back to content

11. 2023 IWG Report, op .cit., page 90. Back to content

12. Ibid, pages 90-91. Back to content

13. 2023 IWG Report, op .cit., page 137. Back to content

14. Ibid, page 93. Back to content

15. Ibid, page 137. Back to content

16. Mainly the BLM, the U.S. Forest Service, the EPA, and the U.S. Army Corps of Engineers. Back to content

17. 2023 IWG Report, op .cit., page 136. Back to content

18. Ibid, page 135. Back to content

19. 2023 IWG Report, op. cit., pages 139. The IWG Report states that the DOE or DOI could be charged with performing future mining research. The Roundtable disagrees with this aspect of the IWG’s findings due to the statutory distinction between critical materials, which are assigned to DOE, and critical minerals, which are assigned to DOI, as discussed in detail in Section 8 of this concept paper. Back to content

20. 2023 IWG Report, op. cit., pages 139 -140. Back to content

21. Ibid, page 140 Back to content

22. Michaux, S. P., The Mining of Minerals and the Limits to Growth, Geological Survey of Finland: Espoo, Finland (2021), Page 16. Back to content

23. Ibid, page 18. Back to content

25. https://www.mineralplatform.eu/investment/exploration-mining-opportunities/mining-ministries Back to content

26. 30 U.S.C. §§ 1601 - 1605 Back to content

27. https://www.energy.gov/sites/default/files/2023-07/doe-critical-material-assessment_07312023.pdf Back to content

28. On June 12, 2024, the House Committee on Natural Resources discharged H.R. 8446 out of committee, making it ready for consideration on the House floor. Back to content

29. https://naturalresources.house.gov/uploadedfiles/testimony_cabrera.pdf. Mr. Cabrera is the Director of the School of Mining & Mineral Resources at the University of Arizona. Back to content

31. Pub. L. 117-58, Division D, Title II, §§ 40207, 40208, 40209 and 40210. Back to content