Listen Now

Introduction and Background

Production of minerals from natural resources has always focused on the primary mineral of value. However, in some mineral deposits, several valuable minerals may be present that can be recovered as byproducts, allowing multiple products to be marketed. Fluctuating commodity prices will influence the economics of producing both the primary and byproduct minerals at any given time.

For example, in a porphyry copper deposit, copper is the primary metal produced and all efforts are invested in optimizing copper recovery and production. Some copper deposits contain precious metals that pay a bonus at the smelter. Molybdenum may also occur and is separated at the milling operation into its own concentrate. In essence, copper pays the bills and the other metals contribute to the mines’ profits.

Recent characterizations of tailings and waste rocks at some mines have revealed that these materials contain low concentrations of one or more critical minerals. In all likelihood, their presence was known but determined to be too low in concentration to recover when the ore was originally processed. However, they are now in high demand as the raw materials needed to manufacture and construct renewable energy infrastructure and technologies making reprocessing tailings and other mine wastes potentially lucrative. Recently enacted policies support recovering critical minerals from previously mined materials. For example, the Infrastructure Investment and Jobs Act of 2021, also known as the Bipartisan Infrastructure Bill1, provides funding for the recovery of rare earth elements from acid mine drainage and mine waste, states that “many critical minerals are only economic to recover when combined with the production of a host mineral,” and defines critical minerals and metals as “any host mineral of a critical mineral.”

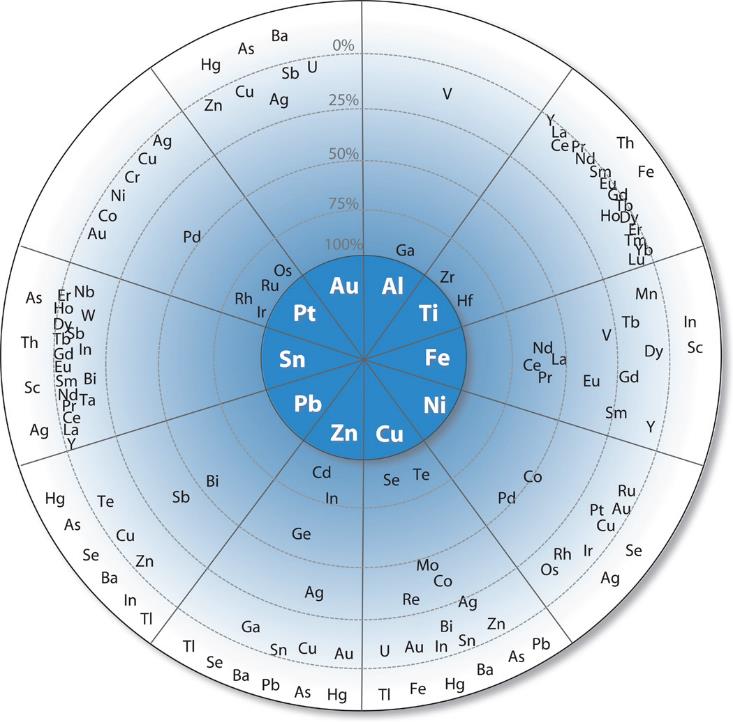

Many critical minerals mainly occur in deposits of other more common minerals. A 2015 study from the Center for Industrial Ecology at Yale University2 discusses the occurrence of by-product minerals in primary mineral deposits and illustrates these occurrences in the “Wheel of Metals Companionality” shown on Figure 1. Many of the by-product minerals are included in the U.S. Geological Survey’s (USGS’) critical minerals list.

Figure 1. Wheel of Metals Companionality

As described in the 2015 study, the principal host metals form the inner, darkest blue circle. Companion elements appear in the outer circles at distances proportional to the percentage of their primary production (from 100 to 0 percent) of the host metal indicated. The companion elements in the white region of the outer circle are elements for which the percentage of their production from the host metal indicated has not been determined.

The Wheel of Metals Companionality illustrates there are many primary metal deposits that have significant potential to produce important critical minerals as by-products or co-products. For example, antimony (Sb), is shown in association with primary (host) mineral deposits of gold (Au), and lead (Pb). Copper (Cu) deposits are a host metal for several critical minerals including tellurium (Te), rhenium (Re), tin (Sn), cobalt (Co), bismuth (Bi), uranium (U), indium (In), barite (Ba), and arsenic (As).

Except for aluminum (Al), the U.S. has significant mineral deposits of all of the host metals shown in the inner, dark-blue circle of the wheel: titanium (Ti), iron (Fe), nickel (Ni), copper (Cu), zinc (Zn), lead (Pb), tin (Sn), platinum (Pt), and gold (Au). Consequently, the Nation’s critical minerals supply chains could be strengthened by developing critical minerals from domestic host mineral deposits.

Opportunities to Produce Critical Minerals from Domestic Host Mineral Deposits

There are several opportunities to produce critical minerals as by-products or co-products from U.S. mineral deposits:

- Recovering critical minerals from mines that are currently producing primary minerals where the host mineral deposit may contain some or all of the by-product or co-product minerals shown in Figure 1;

- Reprocessing mine wastes at active mines, (e.g., tailings, waste rock, or both) that may contain some of the critical minerals by-products and co-products shown in Figure 1;

- Reprocessing tailings and/or waste rocks at inactive and potentially abandoned mines where these wastes may contain valuable deposits of the primary host mineral as well as critical minerals by-products and co-products.

Some companies are actively evaluating recovering by-product minerals from their porphyry copper deposits. For example, Rio Tinto Kennecott recently added a tellurium recovery circuit to its Utah mineral processing facilities in response to the growing demand for this critical mineral and to reduce waste. As explained by Gaby Poirier, Rio Tinto Kennecott’s Managing Director, “Rio Tinto is committed to using innovation to reduce waste in our production process and extract as much value as possible from the material that we mine and process.”

An example of historic mine wastes that contain valuable deposits of both a primary host mineral and a critical mineral is Perpetua Resources’ Stibnite Gold Project in Valley County, Idaho. Perpetua Resources is proposing to redevelop this World War II-vintage mine to produce gold and antimony (a critical mineral) from legacy mine wastes. This proposal, which is currently in the permitting process, will transform this site into a modern, environmentally sound mine that will become the Nation’s only domestic source of antimony.5 The U.S. Department of Defense describes the Stibnite Gold Project as “the sole domestic geologic reserve of antimony that can meet Department of Defense requirements.” Projects like Perpetua Resources’ proposed Stibnite Gold Mine that reprocess legacy tailings and waste rocks represent an opportunity to recover valuable metallic minerals and at the same time cleanup the environment.

An example of historic mine wastes that contain valuable deposits of both a primary host mineral and a critical mineral is Perpetua Resources’ Stibnite Gold Project in Valley County, Idaho. Perpetua Resources is proposing to redevelop this World War II-vintage mine to produce gold and antimony (a critical mineral) from legacy mine wastes. This proposal, which is currently in the permitting process, will transform this site into a modern, environmentally sound mine that will become the Nation’s only domestic source of antimony. The U.S. Department of Defense describes the Stibnite Gold Project as “the sole domestic geologic reserve of antimony that can meet Department of Defense requirements.”6 Projects like Perpetua Resources’ proposed Stibnite Gold Mine that reprocess legacy tailings and waste rocks represent an opportunity to recover valuable metallic minerals and at the same time cleanup the environment.

For industrial minerals and energy minerals, the focus is on the primary commodity. Coal is produced for coal value as thermal coal or metallurgical coal; however, there is an intense interest in processing coal and coal by-products, such as fly ash, for their Rare Earth Element (REE) content. Likewise, heavy mineral sands, where tantalum and titanium oxides are the primary minerals of interest, the tailings offer opportunities to recover REEs. In the case of phosphate production, both REEs and uranium may be recovered as a by-product in refining steps. As a final example, bismuth is also a secondary commodity derived from the primary production of lead as shown in Figure 1.

Project-by-project and materials-specific research are needed to determine if it is feasible to concentrate and extract critical minerals from legacy mine wastes and at currently operating mine sites in a cost effective and efficient manner. This research holds much promise to make a meaningful contribution to creating a reliable domestic supply chain of critical minerals.

In assessing the potential for recovering critical minerals from waste rocks and tailings, it is important for policymakers to understand that the mineralogical and metallurgical characteristics of each deposit are different. Therefore, there will not be a universally applicable blueprint for how to recover critical minerals from previously mined materials. However, research may identify some common results and principles that could be applied in a general way to many deposits.

P.L. 117-58

https://perpetuaresources.com/, during World War II, the U.S. military mined the Stibnite Gold Mine on an emergency basis to produce the Nation’s only source of antimony and tungsten.

https://www.defense.gov/News/Releases/Release/Article/3249350/dod-issues-248m-critical-minerals-award-to-perpetua-resources/.The Defense Department awarded a $24.8 million critical minerals grant to Perpetua Resources to ensure the timely development of a domestic source of antimony trisulfide for the manufacture of small arms and medium caliber cartridges, as well as many other missile and munition items.

Opportunities and Synergies

- The tailings from operations developed since the 1970s have typically been dewatered and placed in engineered impoundments. Thus, there should be relatively few (if any) groundwater contamination at these sites, which should facilitate reprocessing operations.

- For tailings, crushing and grinding (comminution) of the ore has already been performed, which is one of the more expensive stages of processing due to the energy required in the operation.

- For waste rock piles, mining has already excavated these materials, eliminating the first stage of the mining process. In fact, some of these materials have been used as aggregate materials.

Policy Challenges

- Tailings deposits that were created prior to the enactment of modern environmental regulations were typically deposited directly on the ground or into streams without any environmental controls or considerations. These legacy tailings may contain valuable primary and byproduct critical minerals that could be recovered using modern processing technologies, with the new tailings managed in modern, engineered tailings storage facilities. Remining/reprocessing materials to recover critical minerals from pre-regulation sites creates an opportunity to remediate an environmental problem in conjunction with recovering critical minerals, similar to the reprocessing-remediation proposal for the Stibnite Gold Project.

- However, legacy sites with environmental contamination pose challenging Superfund liability exposure issues that are chilling the private sector’s ability to investigate and remediate these sites. Consequently, there are very few reprocessing-remediation efforts like that described above for the Stibnite Gold Mine.

- The decades-long legislative effort in Congress to enact a Good Samaritan liability relief law to protect entities seeking to cleanup old mine sites has been unsuccessful.

- The number of sites where it is economically feasible for a private-sector entity to recover critical minerals from previously mined materials may be limited. Consequently, the federal government may wish to evaluate the public benefits of using taxpayer funds to recover critical minerals from some sites.

- Some sites may be near pristine areas, such as national parks and monuments. Although their remediation may create temporary visual impacts, it must be recognized that it is in the best long-term interests of our country to responsibly recover minerals from these sites to help meet critical minerals demand and at the same time make substantial and enduring environmental improvements.

- Will operating permits for reprocessing/remediation projects be fast-tracked, or will they face the same protracted and uncertain permitting process that currently delays projects and subject to costly and time-consuming litigation?

Technical Questions and Challenges

- Sampling and characterizing old mine waste piles of either waste rocks or tailings to determine potential mineral value presents different challenges than valuation procedures typically used for in-situ mineral deposits.

- The development of a process to extract and recover critical minerals will require the same steps as the development of a new mine:

- Quantification of the resource through drilling and modeling;

- Mineralogical and analytical characterizations are required in order to determine the potential value of the tailings by assessing which elements are present and in what concentration.

- Process testing will be required to establish a baseline process for metallurgical response, similar to determining the extraction and recovery ranges for a new deposit;

- Solutions and solids will require characterization as well as identifying the key reagents required and estimating reagent consumption;

- Regrinding may be required to establish a fresh surface on tailings particles and waste rocks that have been oxidized over time;

- Key design criteria will be required from the testing in order to engineer the facility on a scaled capacity;

- Environmental testing requirements will be required to provide data for permitting the operation and the subsequent tailings disposal and project closure design;

- Will a new impoundment be required or the old one reused; if unlined, it will probably require Hypalon lining;

- Are heavy metals present and are they soluble;

- Is the concentration of the heavy metals in today’s regulations permissible to be disposed or do current regulations require special handling and/or water treatment to manage the resulting effluent;

- Are the tailings capable of being dewatered and disposed according to current regulatory standards;

- Not all tailings are the same and will likely be heterogenous due to a number of factors, namely ore heterogeneity, aging, and operational changes. Because there are typically no records of the tailings placement and assays that go with the material, the tailings will have to be thoroughly drilled and sampled in order to provide a complete resource assessment; and

- What will be the financial assurance requirements for mineral recovery operations?

- Existing impoundments of tailings (coal refuse, fly ash, and other hard rock tailings) may have been reclaimed and are in care and maintenance;

- Who owns the mineral rights to these materials?

- Can the rights be purchased?

- What permits are required to reopen the impoundments and mine the tailings for reprocessing?

- What is the social aspect of the permitting for these materials?

- Have communities grown closer or been incorporated around these impoundments, such that mining the material would create societal concerns about the safety and health of the community?

- The US has no refining or final product manufacturing facilities where mineral concentrates can be sold:

- What pricing regime will be available on contract?

- Will the materials be sold to US companies or will minerals be sold outside the US and who will establish the pricing structure?

- What companies will refine and manufacture magnets and other final products?

- Is the concept of centralized processing facilities (toll milling) viable?

- A comprehensive mineral economic assessment by experienced professionals will be required in order to determine the viability of these resources for producing critical minerals.

Mineral Pricing Challenges

- The Chinese government has driven the REE market, as an example, into the ground:

- Chinese policy dictates that China dominates the market and will use “dumping” of materials as a way to lower price and prevent any new operations from starting up;

- Will the US Government provide import bans from China and prevent the Chinese Government from monopolizing the market?

- Recently, a US cobalt mine was terminated at 90% complete and ready to commission due to the metal price collapse due directly to this dumping. The US Government did nothing to solidify the price of cobalt to facilitate and ensure the start-up of the first cobalt operation in years.

- Without future price-stability assurances from the federal government, private-sector entities may view the government’s failure to support this cobalt project as a major deterrent to developing domestic critical minerals projects.

- Will the US Government purchase materials to control the use of the materials, provide price stability, and prevent the material being sold to China for further refining and manufacturing of critical components as is the currently the norm?

Policy Discussion

In 2021, President Biden issued Executive Order 14017, which directs members of his cabinet to develop policies to increase domestic production of critical minerals to reduce the risks associated with the county’s dependency on mineral imports. The definition of minerals supply chain in Executive Order 14017 “includes the exploration, mining, concentration, separation, alloying, recycling, and reprocessing of minerals.” Evaluating legacy and modern tailings deposits and waste rocks as potential sources of critical minerals is clearly encompassed in the Executive Order 14017 directive.

On March 31, 2022, President Biden signed a determination permitting the use of Defense Production Act (DPA) Title III authorities to strengthen the U.S. industrial base for large-capacity storage batteries and gave the Department of Defense (DoD) the authority to increase domestic mining and processing of critical materials for the large-capacity battery supply chain. Under the DPA Title III, DoD is authorized to provide funding for feasibility studies, and modernization projects for mature mining, beneficiation, and value-added processing projects to increase productivity, environmental sustainability, and workforce safety. It also allows for by-product and co-product production at existing mining, mine waste reclamation, and other industrial facilities.

In order for the critical minerals directives in the Infrastructure Investment and Jobs Act, the “reprocessing of minerals” component of Executive Order 14017, or the Title III DPA funding opportunities to be implemented on a scale that could make a meaningful contribution to the Nation’s domestic critical minerals supply, several things must happen:

- First, in the case of legacy mined materials (e.g., tailings and waste rocks), it is imperative that Congress enact Good Samaritan Liability Relief legislation to facilitate private-sector evaluation and potential investment in reprocessing these materials.

- Second, the federal government should consider subsidizing reprocessing-remediation projects through grants, public-private partnerships, and even taxpayer-funded reprocessing operations.

- Third, the federal government should consider developing incentives to stimulate private-sector evaluation and potential investment in reprocessing tailings for critical mineral recovery at existing mining operations. In some cases, it may not be economically feasible to recover the critical minerals in tailings and waste rock piles without a subsidy from the federal government. Such subsidies could be in the public’s best interests if these deposits contain significant sources of otherwise unavailable critical minerals.

- Fourth, recovering critical minerals from mine wastes at existing mines may be much more economically and technically feasible compared to most legacy sites because of the existing power supplies, mineral processing facilities, equipment, and other infrastructure present at operating mine sites. Also, the existing workforce at an operating mine has the mineral processing and mining expertise to facilitate mineral reprocessing operations to recover critical minerals.

Download PDF